Carrying Cost of Inventory Metric

Measure how much it costs to carry inventory.

Track all your Supply Chain KPIs in one place

Sign up for free and start making decisions for your business with confidence.

Overview

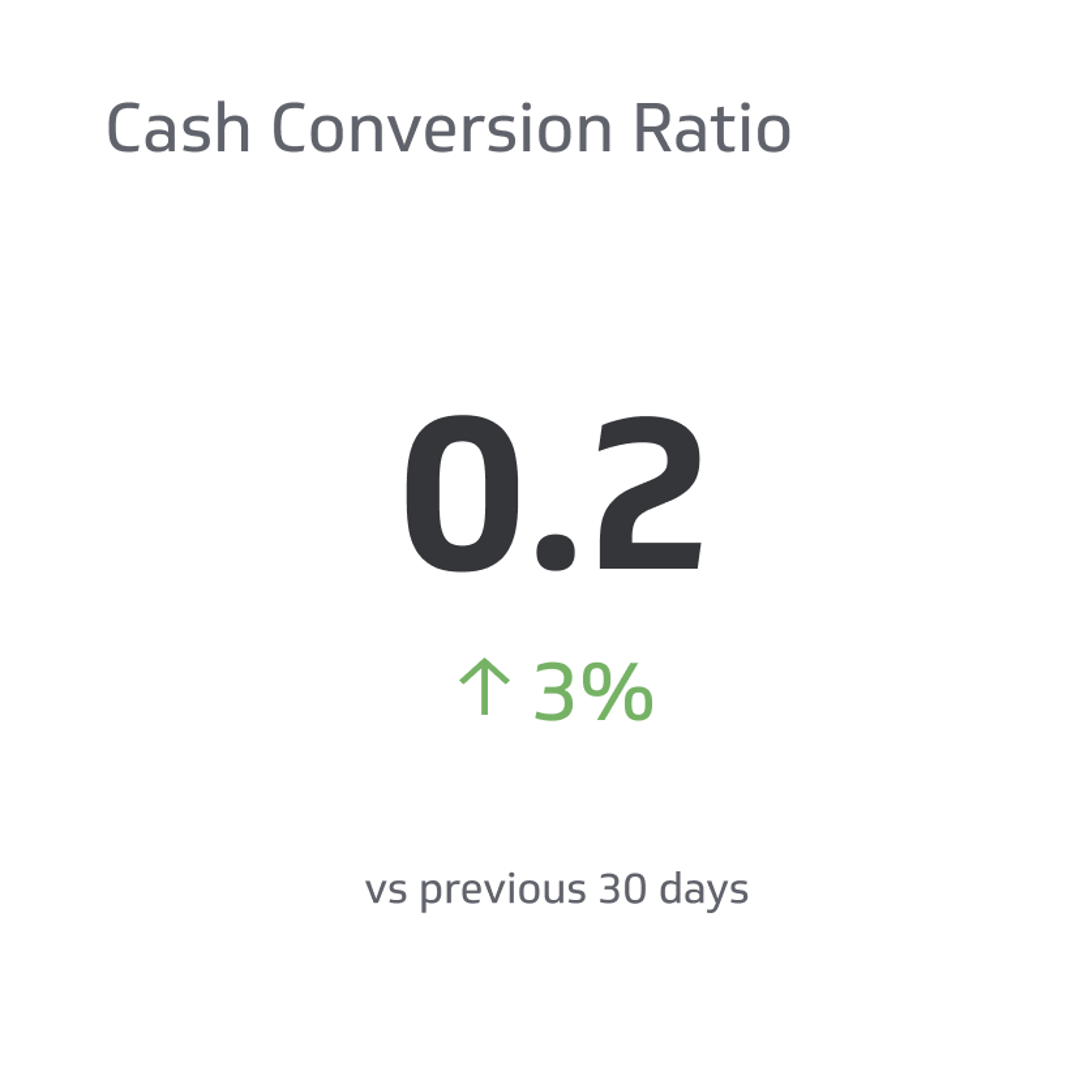

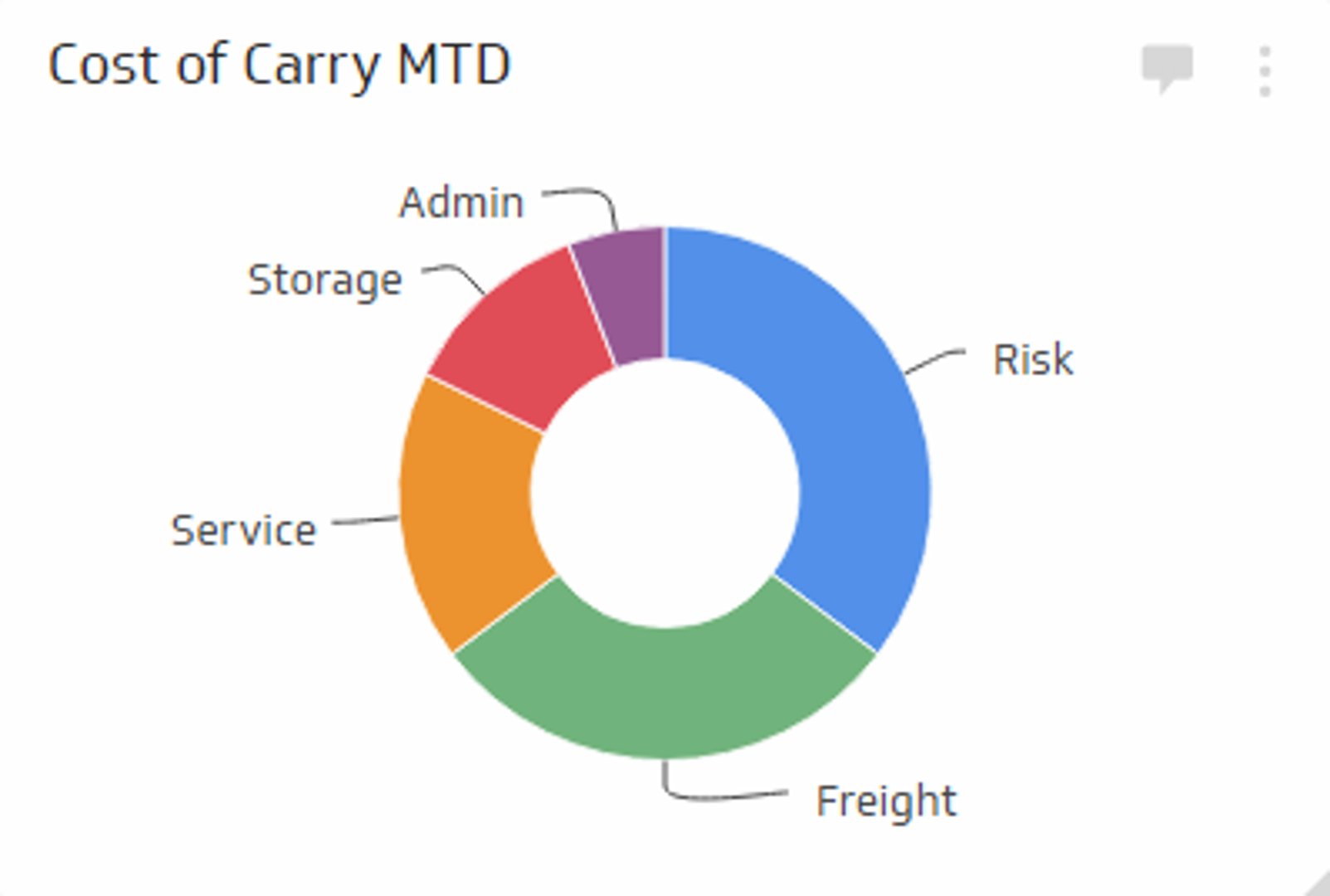

The Carrying Cost of Inventory metric measures how much it costs your organization to store inventory over a given period of time. Use the following formula when calculating carrying cost of inventory.

Inventory carrying rate * Average inventory value

Every piece of inventory that you purchase and store in your inventory has some sort of cost associated with it, such as labour, risk/insurance, storage, and freight. This metric, along with Cash Conversion Cycle is used to figure out how much profit can be made on your current inventory, and it may also be used to help your suppliers map out their production cycles.

Success indicators

- Low costs and high inventory turnover rates.

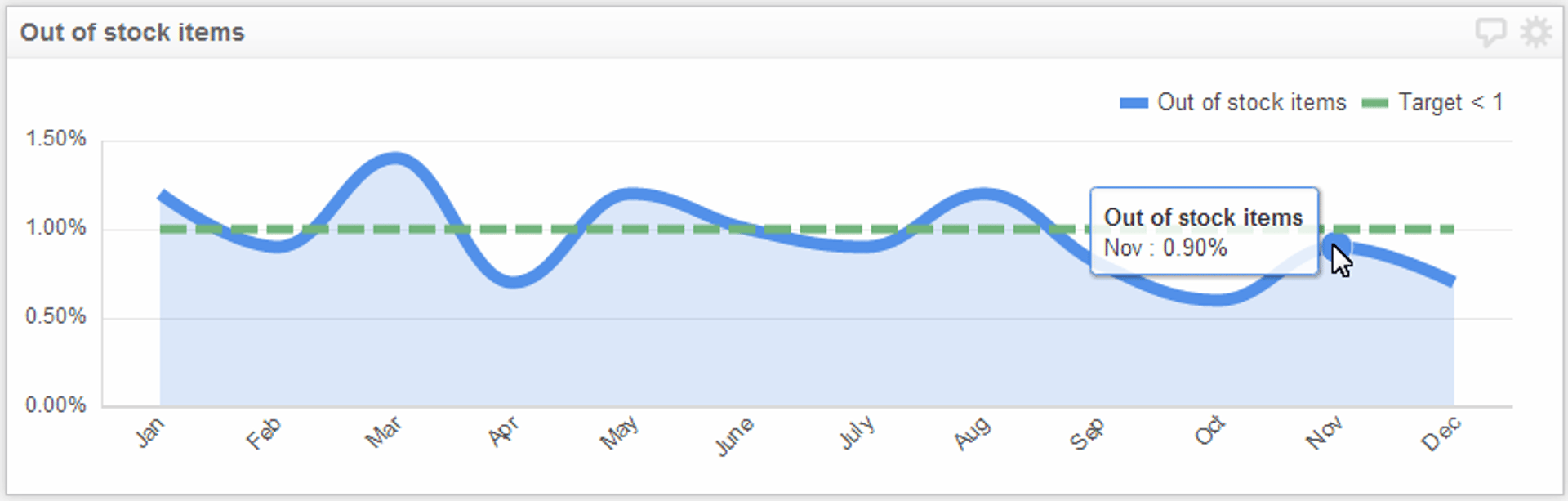

Monitoring Supply Chain KPIs on a Dashboard

Once you have established benchmarks and targets for Carrying Cost of Inventory, you’ll want to establish processes for monitoring this and other supply chain KPIs. Dashboards can be critical in this regard. Read more.

Related Metrics & KPIs