Supply Chain Metrics & KPIs

Metrics and KPIs for modern supply chain operations

Track all your Supply Chain KPIs in one place

Sign up for free and start making decisions for your business with confidence.

In any business, data is king. That’s why business owners, analysts, and managers consistently rely on supply chain metrics to evaluate and improve upon their company’s operations and order fulfillment processes. In fact, according to a Deloitte survey, 79% of companies with reliable, data-driven supply chain metrics perform better and scale faster than those without.

Although most professionals understand the value of running a data-driven business, the sheer number of supply chain metrics and KPIs can make it challenging to determine which to pay attention to.

This guide offers a comprehensive insight into the most valuable supply chain metrics and KPIs, so you can quickly and efficiently assess and improve your supply chain logistics.

What Are Supply Chain Metrics?

Supply chain metrics and KPIs represent the figures that allow you to track how quickly, efficiently, and accurately you are fulfilling orders and delivering goods to customers. This will enable you to measure the degree to which you effectively meet company goals and improve your operations.

Many important supply chain metrics are best used in conjunction with one another to create a complete picture of your business’s performance. When used singularly, they may not give an accurate picture of the productivity in the company’s supply chain processes.

Although all these metrics are essential, not all give value to every type of industry. You’ll need to determine which metrics and KPIs are most important to track.

Why Are Supply Chain Metrics & KPIs Important?

Recent research suggests that data-driven businesses ultimately perform better in the long run, as leaders can make more strategic decisions factoring in facts rather than emotion. This is no different for supply chain metrics.

The Key Performance Indicators (KPIs) can give you a clear picture of your business and determine pain points or areas of strength to make the necessary changes to improve your business. Here is why supply chain metrics & KPIs are important:

- Helps identify the strengths and weaknesses of your supply chain logistics

- Allows for real-time monitoring of performance and the ability to make quick adjustments

- Improves decision-making by providing clear and concise data

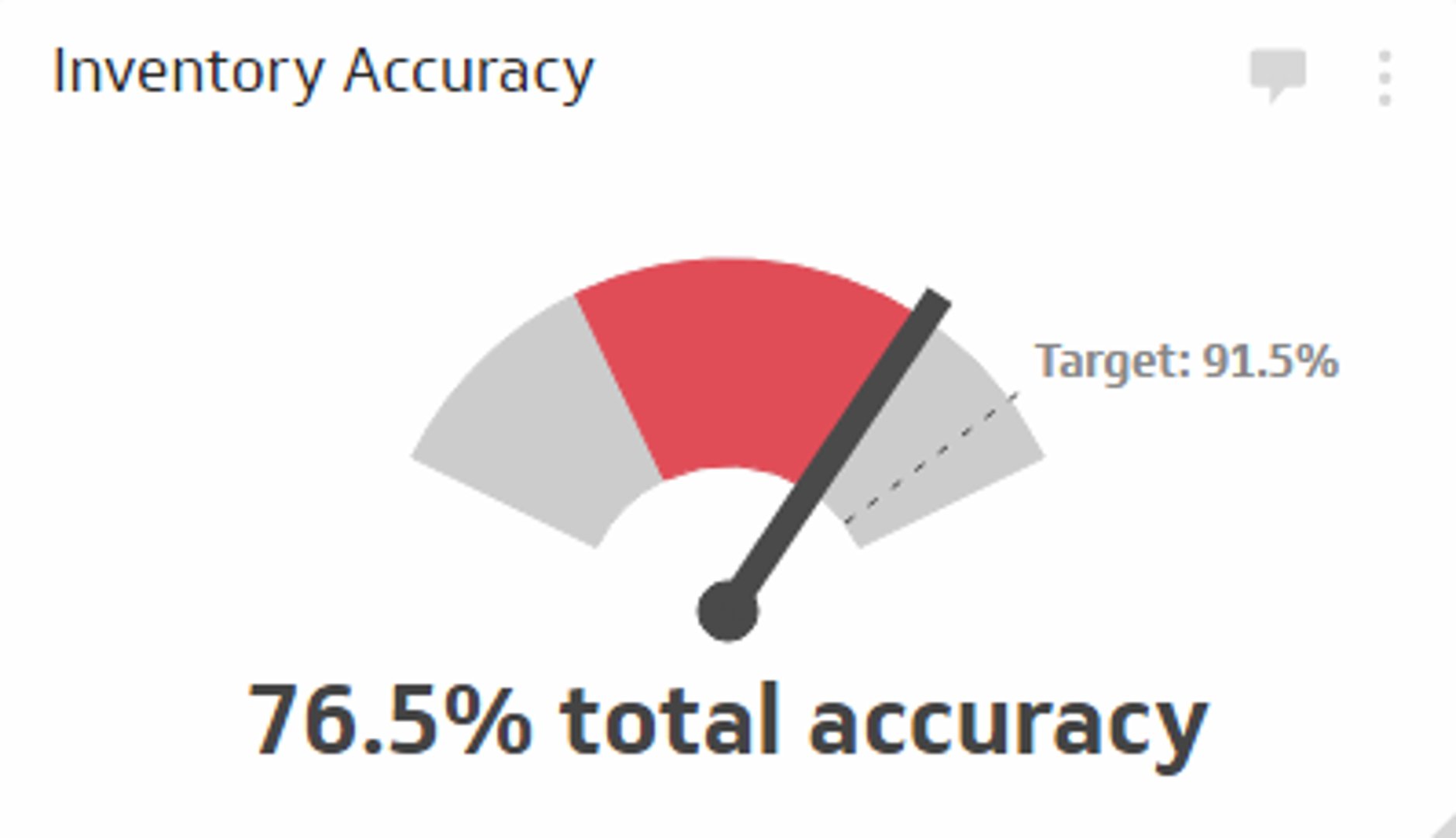

- Increases inventory accuracy, reducing wasted resources and capital

- Helps increase customer satisfaction through faster and more accurate order fulfillment

- Increases efficiency by identifying bottlenecks or areas for improvement in the supply chain process

Now that we understand the importance of supply chain metrics and KPIs, let’s dive into some of the most valuable metrics to track.

22 Most Valuable Supply Chain Metrics & KPIs

Consider the following 22 most valuable supply chain metrics and KPIs to make the most strategic decisions possible.

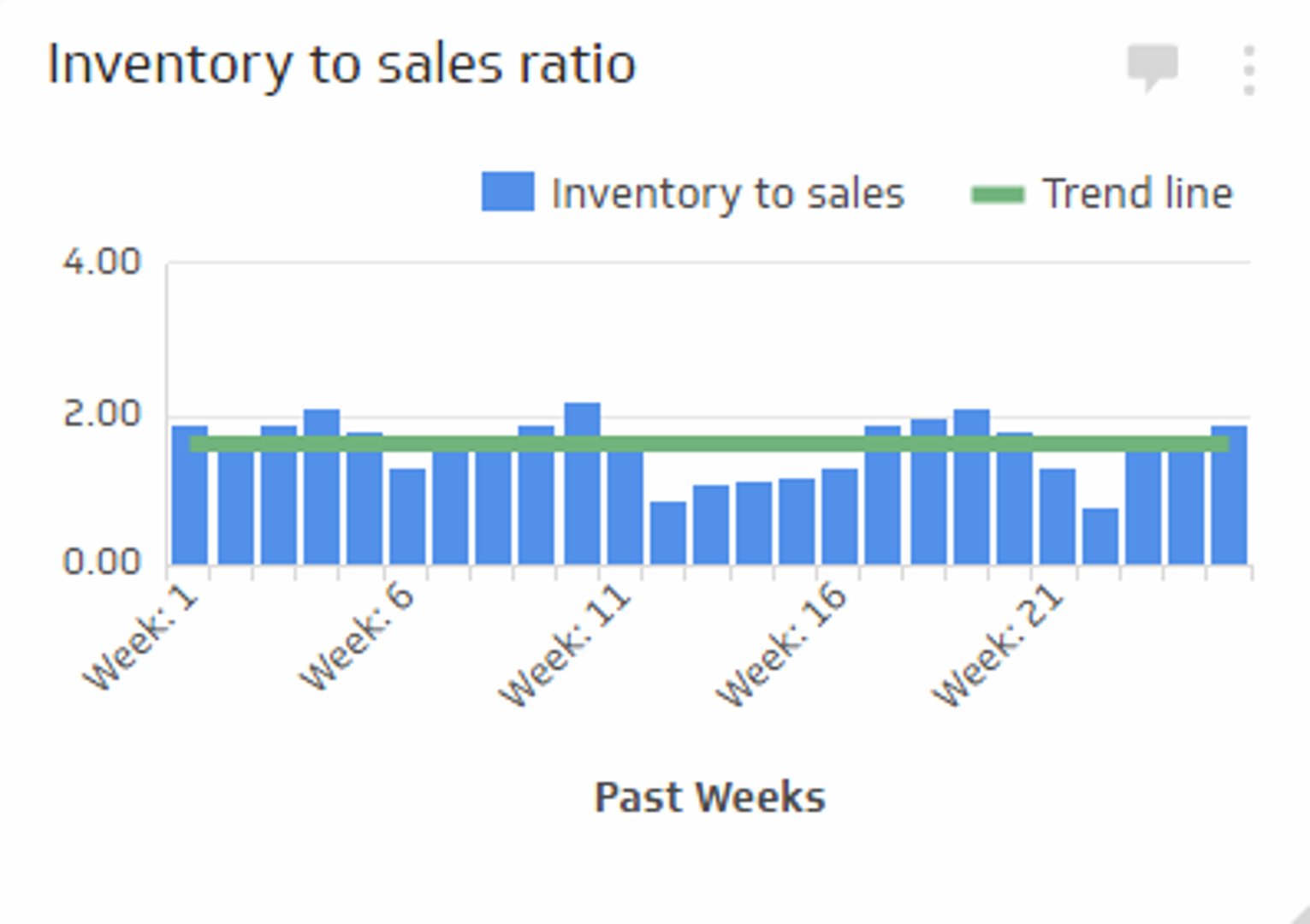

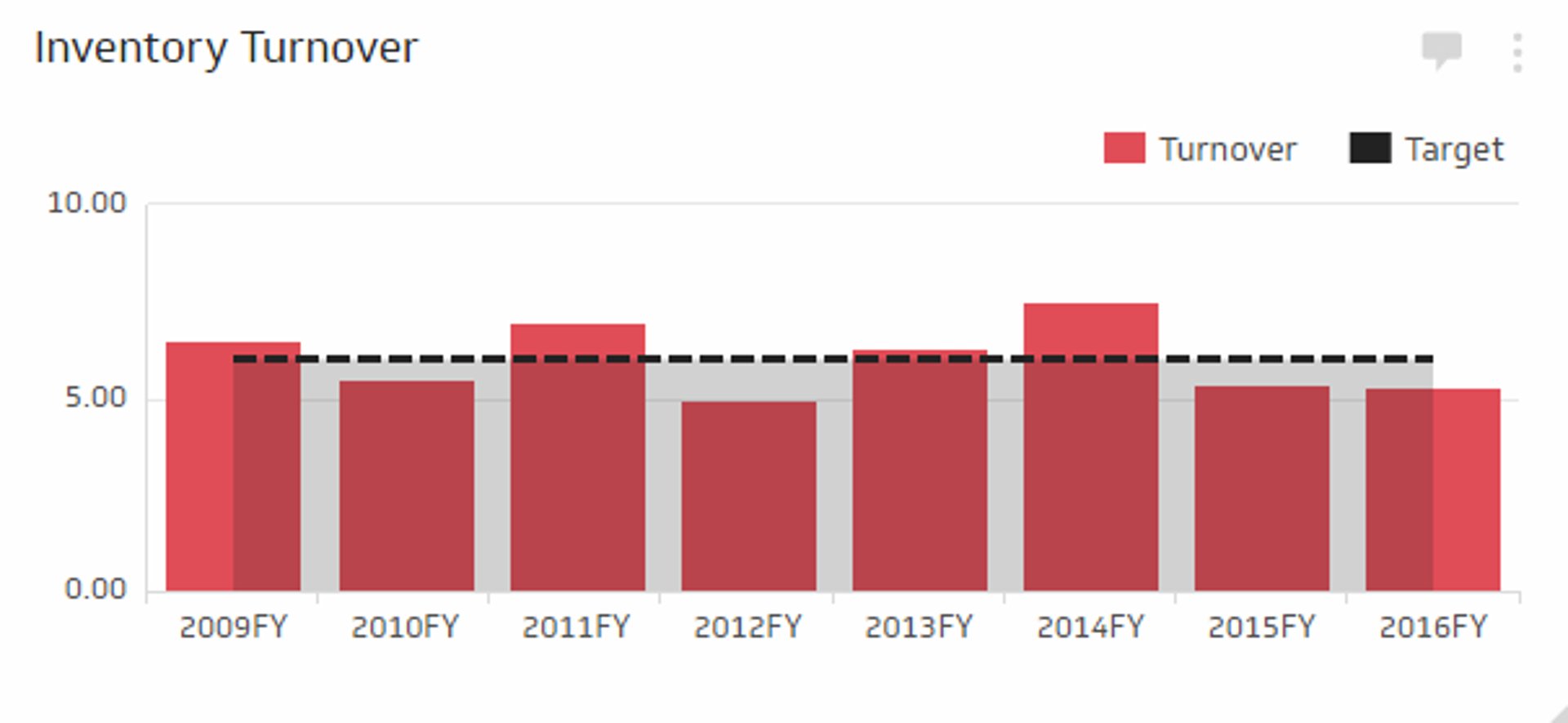

Inventory Turnover Ratio

The inventory turnover ratio measures how frequently a company’s products are sold within a given period. It also lets you determine how often your stock is traded, used, or replaced. With this metric, you can clearly understand how long it takes you to sell inventory.

A slow turn may signal market behavior changes, allowing you to adjust pricing for given products. A high ratio can help you prioritize products and determine when to scale your business.

Understanding your industry's external market factors before acting upon this metric result is essential. For instance, if you are in the fashion and clothing industry, factors such as climate change can lower your turnover ratio for specific goods.

How to Calculate Inventory Turnover Ratio

The inventory turnover ratio is calculated by dividing the cost of goods sold by the average total inventory for a given period

The equation for the inventory turnover ratio is:

Inventory Turnover Ratio = (Cost of goods sold / Average Inventory)

You’ll first need to calculate the average inventory where:

Average Inventory = Start inventory + Final inventory / Months in the accounting period

Therefore in a broader formula, you can represent Inventory Turnover Ratio (ITR) as

ITR = {Cost of goods sold / (Start inventory + Final inventory / Months in the accounting period)}

This figure is most useful when calculated as an average of several different inventory turnover ratios, as this will provide a clearer picture of your situation.

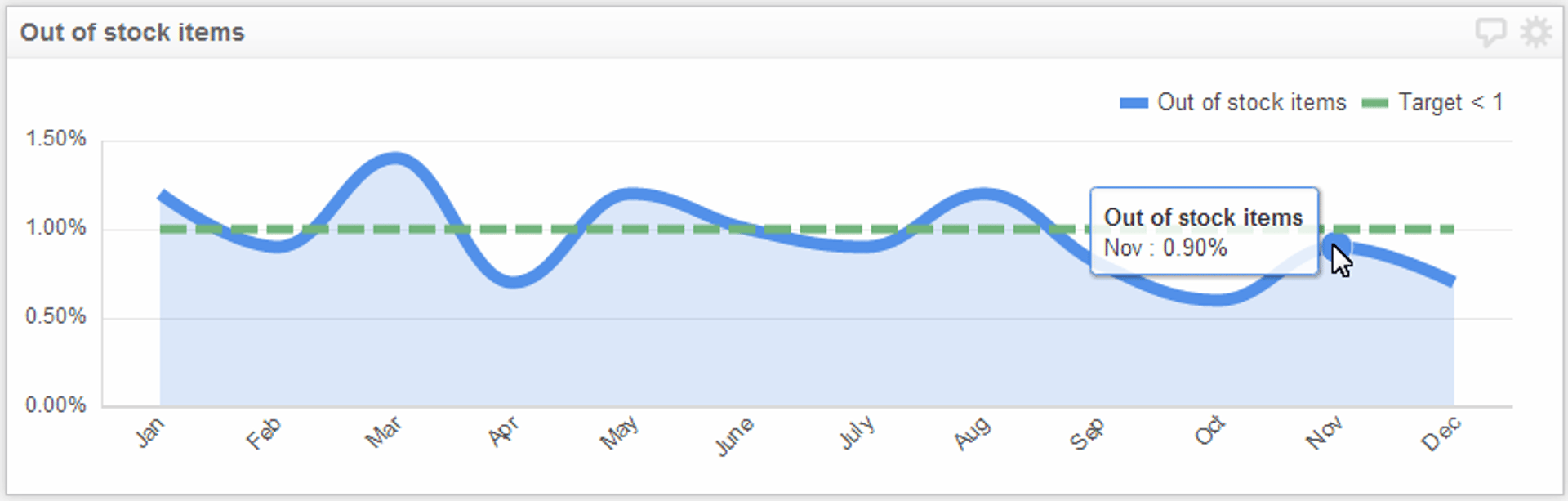

Service Rate

The service rate metric measures the percentage of customer orders or requests your company can fulfill within a specific time frame. This metric is crucial for businesses that need to manage inventory and ensure customer satisfaction.

A low service rate can indicate potential issues in your supply chain that may need addressing, such as stockouts or delayed delivery times. It can also negatively impact customer loyalty and retention.

How to Calculate Service Rate

To calculate your service rate, you will divide the product orders received by the product orders delivered on time.

The equation for the service rate is: (Product orders delivered on time) / (Product orders received)

You can also multiply the final product by 100 to achieve a percentage. The higher the ratio, the better your service rate.

Fill Rate

The fill rate metric allows you to determine the percentage of product orders fulfilled anytime without resorting to backorders and stockouts. The results can help you determine how efficiently your business is fulfilling customer orders, which can lend an understanding of customer satisfaction and overall business health.

Using this metric, you can determine future inventory needs and assess how to reorganize your inventory to manage orders better.

How to Calculate Fill Rate

Determining the fill rate is relatively simple. You will divide the fullfilled or delivered orders by received orders. Then, you can multiply that number by 100 to achieve a percentage.

The equation is:

Fill Rate = (Successful orders / Received orders) x 100

A strong fill rate will be as close to 100% as possible.

On-Time and In Full Deliveries (OTIF)

On-time delivery allows you to determine the percentage of deliveries that arrived on time—and how many were fulfilled in full.

How to Calculate On-Time and In-Full Delivery

To calculate on-time delivery, you must combine your on-time delivery rate (or service rate) and your in-full delivery rate.

Once done, you can use the following equation to determine on-time and in-full deliveries.

- (On-time delivery percentage + in-full delivery percentage) / 2

It is crucial to ensure this rate is high as research shows that 17% of customers are likely to avoid repurchasing from a business after incurring one late delivery. Additionally, customers are less potential to trust a company that does not fulfill its purported obligations.

Damage-Free Delivery

This KPI measures the percentage of your orders that arrived damage-free. The metric is critical to customer satisfaction, which then affects your revenue.

How to Calculate Damage-Free Delivery

The equation for damage-free delivery is as follows.

Damage-Free Delivery = [Total Orders – Orders that are damaged) / Total orders] x 100

A reasonable damage-free delivery rate is as close to 100% as possible.

You can improve your damage-free delivery rate by using strategies such as ensuring there is no empty space or insufficient cushioning in the packaging, preventing improper handling of the product, and protecting goods against theft or negligence by the delivery carrier.

If these strategies do not raise the damage-free delivery rating, it is important to change your transport mechanism to improve the delivery process.

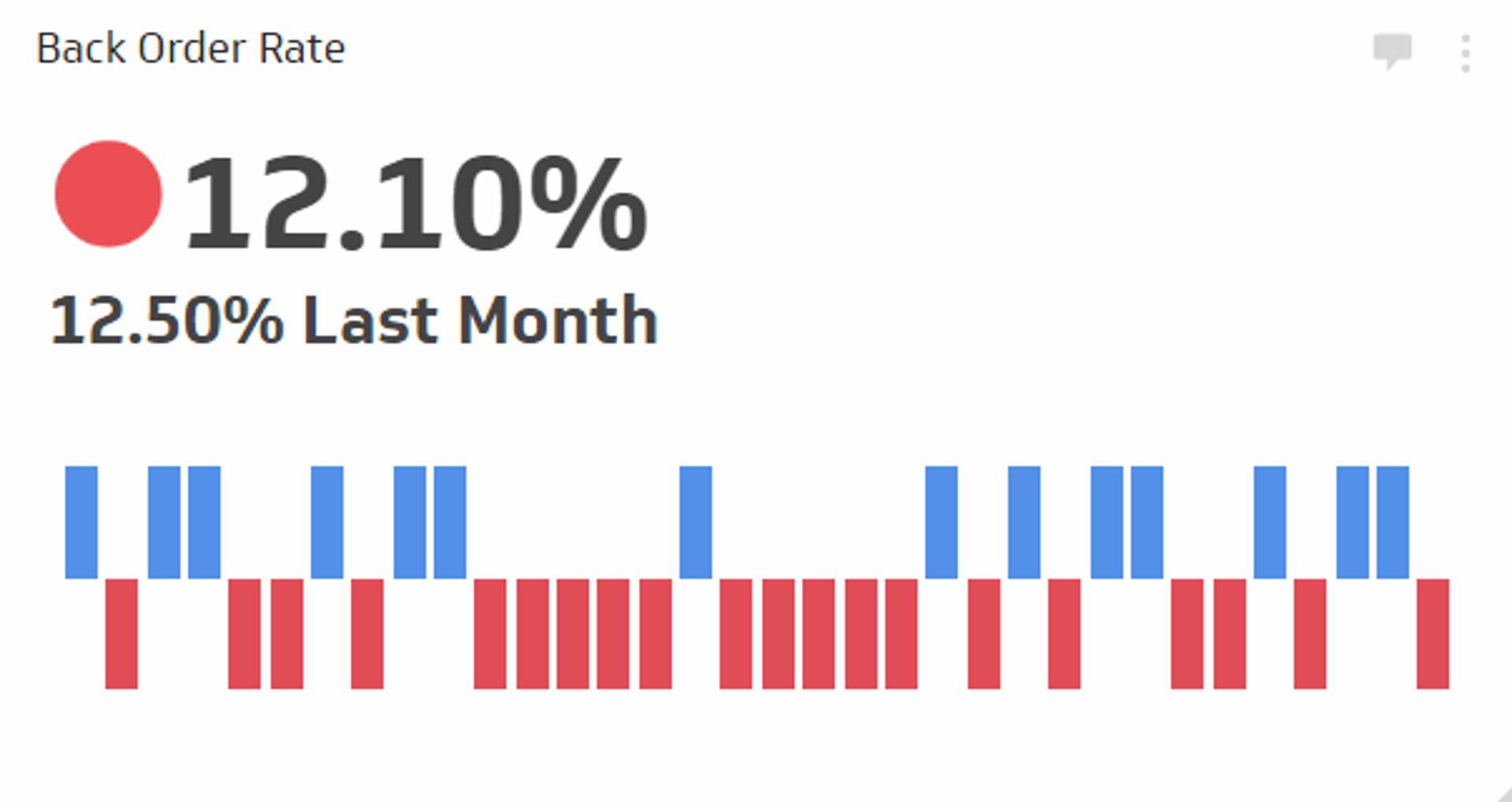

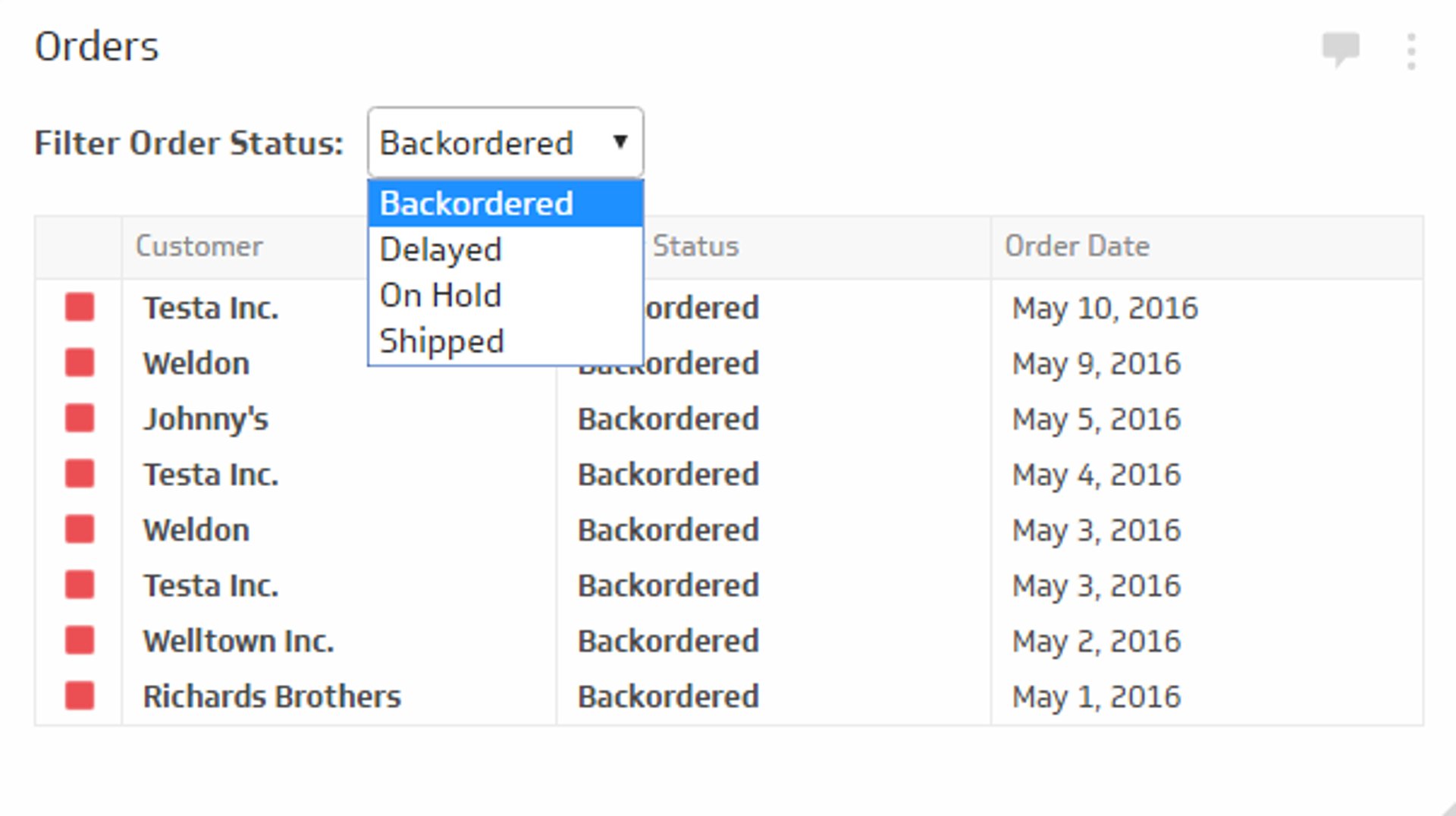

Backorders

Many people conceive of backorders simply as late orders. However, backorders actually consist of orders that cannot be fulfilled when placed, whether because of low inventory, shipping issues, or other standard supply chain problems.

To improve forecast accuracy, you can implement a supply chain planning system or more consistently track relevant key performance indices.

How to Calculate Backorder Rate

To calculate the backorder rate, divide the number of undeliverable orders by the total number of orders and multiply the product by 100.

The equation for the backorder rate is:

Backorder = Number of undeliverable orders / Total number of orders x 100

A high backorder rate can indicate problems with your forecast accuracy.

Rate of Return

The rate of return KPI allows you to measure how your customers return your items.

How to Calculate Rate of Return

To calculate the rate of return, you’ll need to divide the total items shipped by the total items returned.

You can calculate the rate of return using the following equation.

Rate of Return = Total items returned / Total items shipped

A high rate of return indicates that customers are dissatisfied with their products, so you might have to adjust your operations to improve the quality of the product or assess your product descriptions and ensure that they align with the details of the item itself.

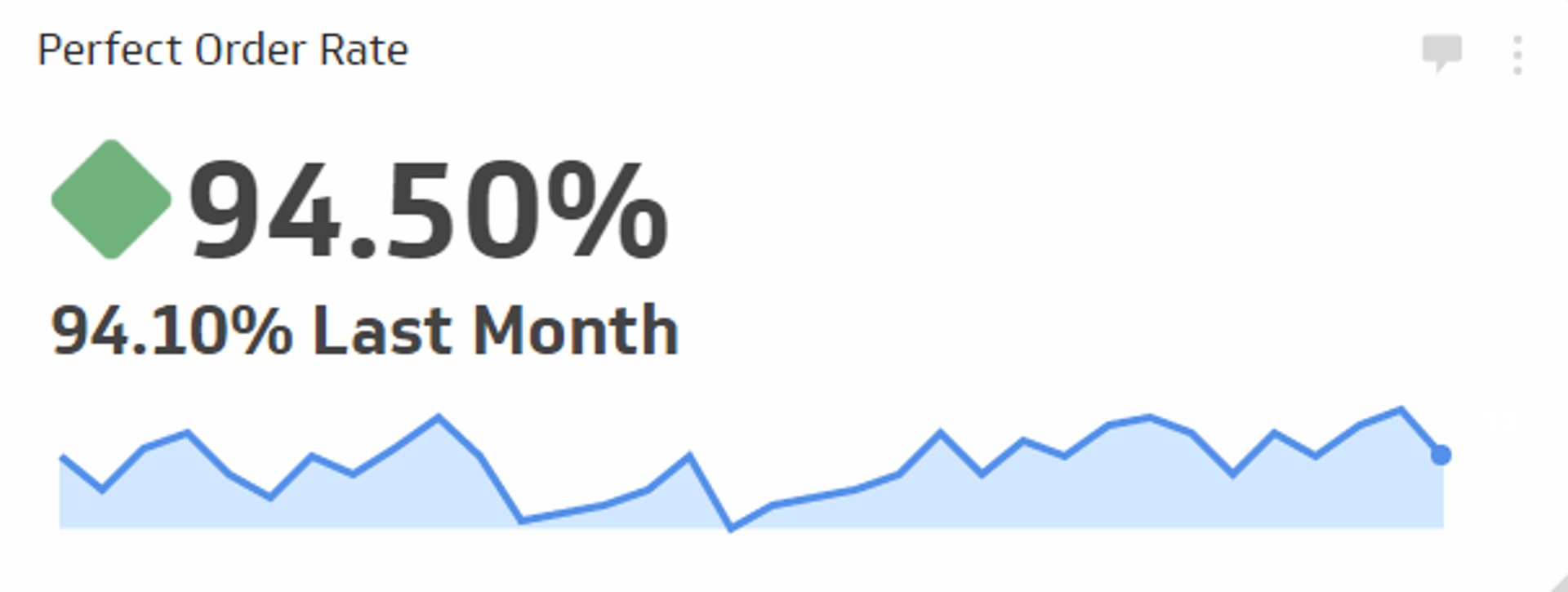

Accurately Documented Orders Rate

Documenting orders is crucial since it allows you to track and analyze other important metrics like fulfillment rates and customer service statistics. Tracking your perfect order rate will enable you to determine which percentage of your documents are accurate and representative of the order's details.

How to Calculate Accurately Documented Orders Rate

You can calculate accurately documented orders by subtracting total orders from the charges without accurate documentation. Then, divide that number by the total number of orders. You’ll then multiply that number by 100.

The equation for accurately documented orders is:

Accuracy Documented = [(Total orders – Orders without accurate documentation) / Total orders] x 100

You can calculate your perfect order index by multiplying ideal order rates across varying categories. You’ll use metrics for types like on-time delivery, in-full delivery, and damage-free delivery. You can then multiply those numbers to assess the overall index more accurately.

Cash-to-Cash Cycle Time

Cash-to-cash cycle time allows you to determine the time between when you have paid suppliers for materials and when the customer pays for the final product. This allows you to identify and resolve cash flow issues.

How to Calculate Cash-to-Cash Cycle Time

You can determine the cash-to-cash cycle time metric by using three other metrics: days sales outstanding (receivable days), days inventory outstanding (inventory days), and days payable due (payable days).

The equation is:

Cash-to-Cash Cycle Time = Receivable days + Inventory days – Payable days

If you have a negative cash-to-cash cycle time, you generate positive cash flow, as your customers pay you faster than your suppliers.

A positive cash-to-cash cycle time means you might be experiencing cash flow issues, as you are paying your suppliers before receiving payment from your customers. In this case, you might need to reassess your business operations to improve your cash flow.

Customer Order Cycle Time

Your customer order cycle time metric allows you to track the days between the moment you receive a purchase order and the delivery time. This metric is crucial in empowering you to identify and handle responsiveness issues in your supply chain, affecting customer satisfaction.

How to Calculate Customer Order Cycle Time

To calculate customer order cycle time, subtract the actual delivery date from the purchase order creation date. The equation is as follows.

- Actual delivery date – Purchase order creation date

The shorter the cycle time, the better. However, according to experts, cycle time can vary significantly from business to business, so assess competitor metrics within your industry to improve your understanding of this metric.

Supply Chain Cycle Time

The supply chain cycle time metric measures the length of time between placing an order for raw materials or supplies and the delivery of the final product to the customer. This metric is critical in assessing how efficiently your company manages its supply chain from start to finish.

How to Calculate Supply Chain Cycle Time

To calculate the supply chain cycle time metric, subtract the order receipt date from the shipment date.

The equation is:

- Shipment date – Order receipt date

The shorter the cycle time, the more efficient your supply chain is. A longer cycle time may indicate issues in your supply chain, such as poor communication among teams or supply chain partners.

Freight Bill Accuracy Rate

This metric measures the number of total accurate freight bills within your company. This number can help you identify and track problems with billing operations.

How to Calculate Freight Bill Accuracy

To calculate freight bill accuracy, divide the total freight bills by the number of correct freight bills. Then, multiply that number by 100 to yield a percentage value.

The equation is calculated using the following formula.

Freight Bill Accuracy = (Number of correct freight bills / Total freight bills) x 100

The ideal freight bill accuracy rate is 100%. Any discrepancy in this number indicates a possible problem, so even a number as high as 99% requires further investigation.

Freight Cost Per Unit

Shipping costs can cut your ROI. The freight cost per bill metric allows you to identify freight expenses and patterns in your spending. You can then use this number to optimize the shipment process and reduce expenditures.

How to Calculate Freight Cost Per Unit

To calculate freight cost per unit, you must divide the units shipped by the overall freight cost.

The equation is as follows.

Freight Cost Per Unit = Overall freight cost / Number of units shipped

It is essential to measure this metric over a period to note the trends and patterns. You can also break this metric down further by calculating the freight cost per unit for each shipping method, allowing for a more in-depth analysis of each method's effectiveness and cost efficiency. This information can aid in selecting the most cost-effective methods for future shipments.

Gross Margin Return on Investment

The gross margin return on investment is an inventory profit assessment ratio determining a firm’s efficacy in turning inventory into cash. It is a more sophisticated way of assessing revenue (profit minus loss). This metric allows you to identify the average profit your inventory turns into.

How to Calculate Gross Margin Return on Investment

To find the gross margin return on investment, you’ll need to divide the gross margin by the average inventory cost.

The equation for this metric:

Gross Margin Return on Investment = Gross Profit / Average inventory cost

Your ratio should be higher than one, indicating that you are turning a profit on products above and beyond your initial investment.

Days Sales Outstanding

Days sales outstanding metric measures the average number of days to collect payment after a sale, typically a year, quarter, or month. This metric is critical for managing cash flow and ensuring timely customer payments.

How to Calculate Days Sales Outstanding

You can divide the accounts receivable by the total number of credit sales. Then, multiply this number by the days you wish to include in the day's sales outstanding rate.

The formula is:

Days Sales Outstanding = (Accounts receivable / Credit Sales) x Days

A high day's sale special rate can indicate a problem with credit collection. A low days sale outstanding rate can indicate a rigid credit policy affecting overall revenue. Ultimately, your rate should be stable over time and around 45.

Warehousing Costs

Warehousing is integral to any supply chain company, but high warehousing costs can cut your profit margins.

Reviewing your warehousing costs can help address supply chain issues and determine your company’s profitability. You can then decide if your warehousing company is adjusted to your needs.

How to Calculate Warehousing Costs

To calculate your warehousing costs, you’ll need to add up your total annual overheads (rental expenses, utilities, insurance, and equipment expenses) and divide by the total number of products stored in that warehouse.

The equation for warehousing costs is:

Warehousing Costs = Total annual overheads / Total number of products stored

Once you have this number, you can compare it with industry standards to determine whether your costs are reasonable and make adjustments as necessary.

Units per Transaction

Units per transaction is a metric that measures the average number of units sold per customer transaction. This metric is valuable because it allows you to assess your sales and marketing strategies' effectiveness.

A higher number of units per transaction indicates that customers purchase more of your products than average, which could indicate your business is doing well. You can optimize your sales to replicate and improve this behavior.

How to Calculate Units per Transaction

To calculate units per transaction, you will divide the total units sold by the total number of transactions.

The equation is as follows:

Units per Transaction = Total units sold / Total number of transactions

You can then benchmark this number against your industry's standards and compare it with competitors in your industry.

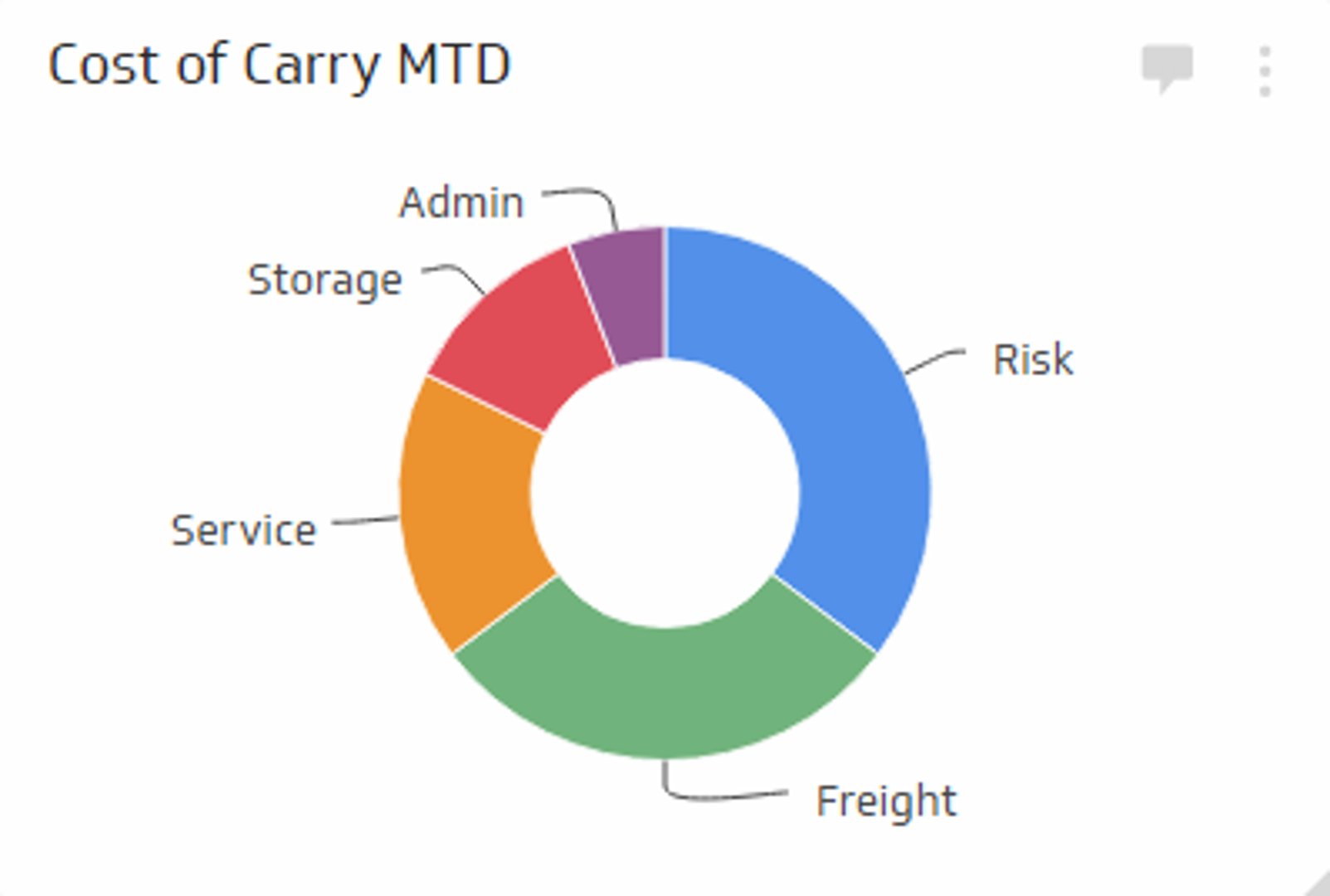

Supply Chain Costs

Calculating your total supply chain costs is the precursor to identifying your ROI. These costs can significantly cut your business, affecting metrics such as gross margin return on investment.

Analyzing supply chain costs can help you identify pain points and potential areas of improvement in your operations, maximizing your ROI. You can also use supply chain costs to determine your profit rate against the number of sales you facilitate.

How to Calculate Supply Chain Costs

To calculate your total supply chain costs, you must add up your inventory carrying costs, logistics costs, and procurement costs. You can then divide the total supply chain costs by the total number of products sold to determine the per-product supply chain cost.

The equation for supply chain costs is:

Supply Chain Costs = (Total inventory carrying costs + Total logistics costs + Total procurement costs) / Total number of products sold

If the values are high in comparison to your competitors or industry standards, you may need to evaluate your operations and identify areas where you can reduce costs.

Supply Chain Costs vs. Sales

Supply costs vs. sales is a metric that determines your business's efficiency in managing costs related to the sales generated. It shows your business's profitability by comparing total supply chain costs to total sales.

How to Calculate Supply Chain Costs vs. Sales

To calculate the supply chain costs vs. sales ratio, you need to divide the total supply chain costs by the total sales amount.

The equation is as follows:

Supply Chain Costs vs. Sales = Total Supply Chain Costs / Total Sales Amount

A ratio closer to zero is preferred, indicating that your business is efficiently managing its supply chain costs in relation to its sales generated.

A higher ratio of supply chain costs to sales can indicate that your business spends too much on supply chain management relative to its sales. Here, you need to identify and address possible inefficiencies in your supply chain operations.

Cost of Quality

The cost of quality metric measures the total cost of ensuring quality control in operations to provide quality products to customers. These costs can include inspection, testing, equipment, rework, and other expenses.

Measuring the cost of quality will help you assess how much it costs to maintain quality control in your operations.

How to Calculate Cost of Quality

To calculate the cost of quality, you will need to add up all the expenses incurred to ensure quality control in your business and divide it by the total number of products produced.

The equation for the cost of quality is:

Cost of Quality = Total expenses incurred for quality control / Total number of products produced

This metric can help you identify the areas where quality control expenses are being allocated and potentially reduce these costs to maximize your profits.

Turn-Earn Index

The turn-earn index combines the gross margin and the inventory turnover rate to yield a number that balances inventory availability with profits earned.

How to Calculate Turn-Earn Index

To calculate this number, multiply the inventory turnover ratio by the gross profit percentage and multiply that final number by 100.

The equation is as follows.

Turn-Earn Index = (Inventory turnover ratio x gross profit percentage) x 100

This number is handy because it recognizes that different products are priced differently.

Pick and Pack Cycle Time

Pick and pack cycle time refers to the time it takes for your company to source and package your products to prepare for shipping.

How to Calculate Pick and Pack Cycle Time

To calculate pick and pack cycle time, you’ll subtract the start time for order fulfillment from the time of order completion. The equation is:

Pick and Pack Cycle Time = Time of order completion – Start time for order fulfillment

Determining this number allows you to assess the efficacy of your warehouse storage and product fulfillment operations.

Wrapping Up

Supply chain metrics & KPIs are the secrets to any business success. They can give you a firm grasp of your company’s affairs, allowing you to finetune your operations and fulfillment processes. This can maximize your ROI (return on investment) and scale your business to more profits and significant growth.

Contact us for professional help to determine your business's most valuable KPIs and metrics. See below KPI examples to learn more about tracking your Supply Chain performance.